Consigned Material

If you’ve arrived at this page you have either designed a board and placed an order with us, or are considering doing so and would like to consign some or all of your own material. In order to make sure your build goes smoothly, we need to make sure that the components you’ll be consigning to us are useable in our manufacturing process and that we can easily identify them when they arrive. If you don't want to hear the gritty details and just need to know our specific requirements, feel free to jump ahead to the "Supplying Extra Parts" or "Material Identification" sections. But if you're curious as to why we have these requirements, then read on.

"If you've failed to plan, then you've planned to fail."

First of all, if you've ever purchased parts for a low quantity prototype and hand soldered everything together then you've probably never had to really worry about the issues associated with accounting for attrition. When you're manufacturing with high speed machinery this is something essential to be taken into account to ensure that you get your boards on time.

At Worthington Assembly we use high speed equipment to populate all of the surface mount parts. There are 2 reason that we will need more than the exact quantity of parts.

Loading feeders will waste a small quantity of parts

Machines will reject parts occasionally for a variety of reasons and potentially be lost forever

Loading Feeders

When you first load an SMT feeder you need a small amount of "leader tape" for the machine to grab so that it can finally advance the whole reel of parts. This holds true whether it's a full reel or just a small amount of cut tape. The following video shows how we load one of our feeders. In order for the machine to advance the tape, it needs to gain access to the sprocket holes of the tape. The machine needs at least 3 empty sprocket holes to begin this process.

When the tape is loaded into the feeder, the cover tape is not actually peeled completely off. It is only folded over. The glue on the sprocket side of the carrier tape holds the cover tape in place while the glue on the opposite side of the tape is peeled off by the plow of the feeder. You can see in the video the cover tape peeling over and a few seconds in you'll hear a "click" as the tape snaps into position.

When we pull the tape back we are deliberately leaving those 3 sprocket holes past the "pick point" of the feeder. The pick point is that area where the component is exposed, past the "4.0" marking and before the cross bar.

Finally, this feeder is inserted into a magazine. This magazine has a mechanism for advancing the tape in the feeder. There is a shaft with two pins, riding on a moving platform. This shaft gets pushed up by a solenoid from below and when it does the two pins sitting on top of the shaft get inserted into the sprocket holes of the tape. This shaft then moves forward the appropriate amount, based on the pitch between components, and the tape advances. Because of the way the whole system is designed, there needs to be 3 exposed sprocket holes for the process to get started.

Here's a video showing the mechanism that moves forward and backward. The shafts with pins are the dark plastic pieces you see riding on the advancement mechanism. Hidden below are the solenoids which push those plastic shafts up into the sprocket holes.

Because these feeders need 3 exposed sprocket holes, that means the very first time you load a feeder, no matter how long or how short the amount of tape, you will always waste a few parts. Generally it's 3 to 6 parts, depending on the pitch of components. If it's a larger part it may only be 2 parts, but regardless, these parts will need to be "lost" for all intents and purposes. Granted, we don't actually throw these away, we put them in the bag that's associated with the part number, but regardless, if we had to use these parts again a significant amount of time would be required to reload the part into the feeder so that the pick and place machine can finish the job. And time is money as they say. Trust us, you don't want to pay an experienced and highly professional operator to manually reload parts into the pocket of a piece of tape. It's much less expensive to just order extra parts.

2. Machine Rejects

Another reason that we need extra parts, is because these pick and place machines are super fast and have lots of little holes and pockets for little tiny surface mount parts to get lost in. It's not unusual for a machine to reject a part and then toss it into a rejection bin which we can pull out and sort through to find any parts that were rejected that we still need. However, sometimes because of an enormous number of variables (which are beyond the scope of this article) the machine may lose the part completely in its vast array of pockets for stuff to get lost. In these circumstances, it's necessary to make sure we have extra parts, should any one of these parts get lost. In general, the cost of an individual part is far less than the cost of the whole assembly (there are exceptions of course but we're going to speak in generalities here). So when we order parts we make sure to order extra.

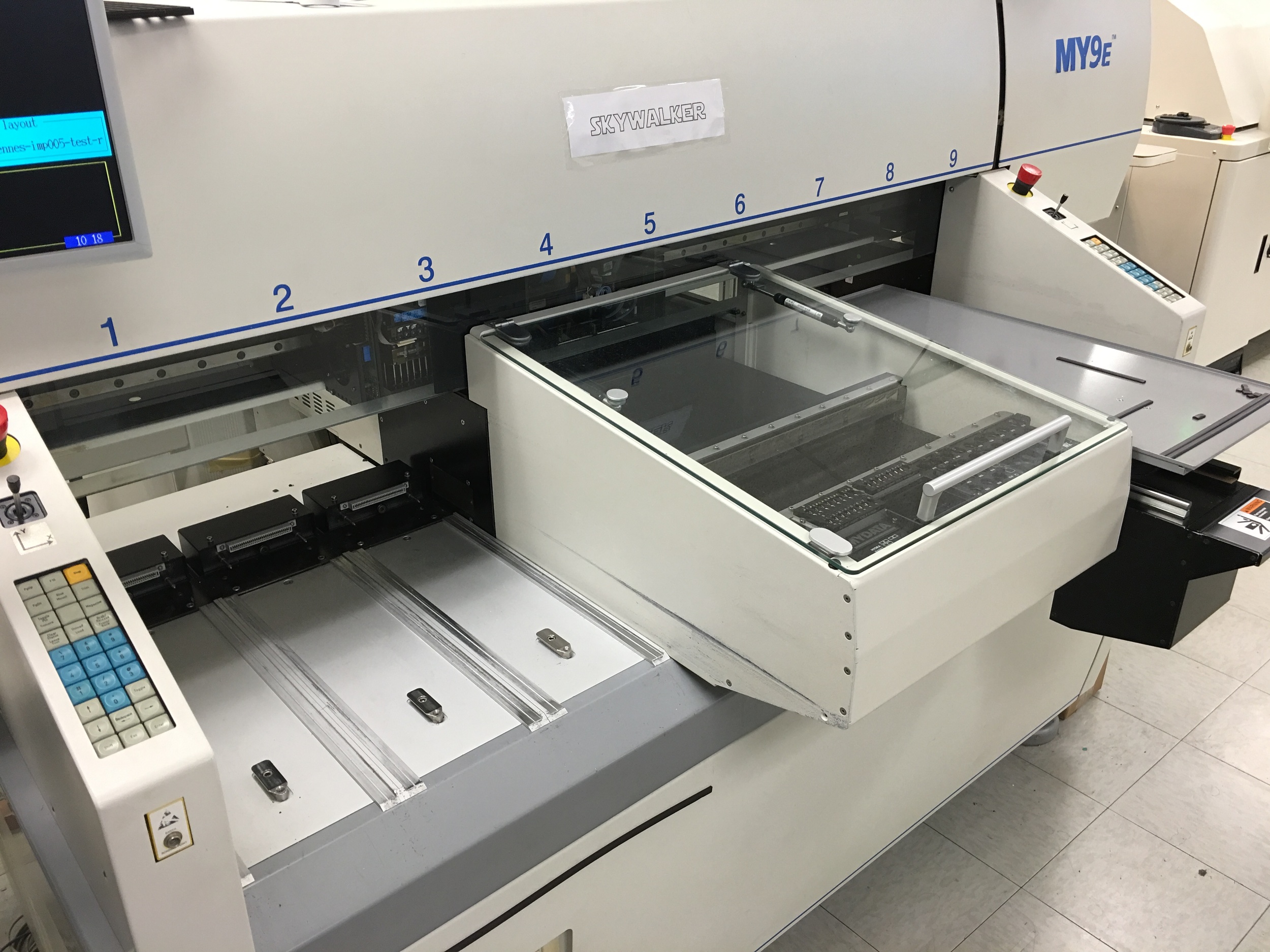

Here's a picture of one of our pick and place machines (affectionately named "Skywalker"). You can see a whole lot of shapes and pockets where things can get lost. If you look at one in person then you'll see clearly just how easy it can be to lose parts in here.

Pick and place machine

Supplying Extra Parts

(Dealing With Attrition)

Surface Mount

All surface mount material must be shipped either in continuous tape, trays, or tubes. We cannot accept multiple pieces of cut tape for the same part number. It would require us reloading that part into a feeder over and over and we do not quote our services based on having to do this kind of work. We expect to be able to load the part once and let the machine run. Loose material will only be accepted if we are notified first and there's a reasonable explanation for the material being loose (we're reasonable people).

Discrete Passives (cheap caps, resistors, inductors, etc.)

01005 Package Size - 50% extra - 200 pieces minimum - at least 100 extra

0201, 0402 Package Size - 50% extra - 100 pieces minimum - at least 50 extra

0603, 0805 Package Size - 10% extra - 25 pieces minimum - at least 20 extra

1206 and Larger Package Size: 5% extra - 10 pieces minimum - at least 5 extra

Inexpensive Active Devices (small diodes, LED's, regulators, transistors, crystals, etc.)

0.6mm or smaller - 20% extra - 20 pieces minimum - at least 15 extra

0.6mm - 1mm - 10% extra - 15 pieces minimum - at least 10 extra

1.0mm - 2mm - 5% extra - 5 pieces minimum - at least 5 extra

2mm or larger - 5% extra - 5 pieces minimum - at least 5 extra

Moderately Expensive Devices (regulators, drivers, crystals, inductors, connectors, etc.)

0.6mm or smaller - 10% extra - 10 pieces minimum - at least 5 extra

0.6mm - 1mm - 5% extra - 10 pieces minimum - at least 5 extra

1.0mm - 2mm - 3% extra - 5 pieces minimum - at least 4 extra

2mm or larger - 2% extra - 3 pieces minimum - at least 3 extra

Expensive Devices (MCU, memory, large inductors, sensors, wireless modules, etc.)

Most of these expensive parts should be handled on a case by case basis. Suffice it to say, we'd generally like at least 1 extra but understand that there may be times where exact count is necessary. We will still need extra if the components are very tiny though. The smaller the component, the more trouble we will have getting the pick and place machine to reliably do its job.

Price Breaks

Here's a quick tip. Look for price breaks when purchasing material. Although you may only need a small volume of components, it is often cheaper (especially for caps and resistors) to buy more than you need, saving both money and providing us parts to account for wastag

Thru-Hole

Inexpensive Devices (resistors, caps, LED's, etc.) - 5% extra - 10 pieces minimum - at least 5 extra

Moderately Expensive Devices (connectors, regulators, etc.) - 2% extra - 5 piece minimum - at least 2 extra

Expensive Devices - exact counts are ok, but please notify us ahead of time

Hardware

Inexpensive (less than $0.25) - 10% extra - at least 5 extra

Moderately Expensive ($0.26 - $1.00) - 2% extra - at least 2 extra

Expensive ($1.00 or more) - 1% extra - at least 1 extra

A Note About Insufficient Attrition

If we do not receive enough extra material, we will still build your assemblies to the best of our abilities but we will complete the assemblies short of whatever material we run out of. In other words, you will receive assemblies with missing parts. We will communicate all of this to you when this happens of course.

Material Identification

When you send us your materials, it is an absolute requirement that the materials and the shipment itself is clearly labeled with all of the necessary information. If it is not, then we will not know who the material belongs to and you may only hear from us once we're concerned that your material never arrived.

Identifying Individual Part Numbers

Each part number should be in its own separate package, be it a reel, a bag, a tray, or a tube. Each package of components should be clearly marked with the specific manufacturer's part number. This should match your BOM exactly. For the sake of our sanity, please do not write a partial part number on the package. Write the full and complete part number as we are expecting to identify it. If you have a cross (a part number that's equivalent to what we need but not the exact same manufacturer's part number) please communicate this to us ahead of time.

Distributors will often put a manufacturer's part number on their label. In this case, so long as that label is clear and legible, their label will work great. Here is an example from Digikey. These work really well.

Part number clearly identified

Packaging

All material should come in a qualified package. We cannot accept parts that are loosely packaged. Many (nearly all) electronic component are extremely fragile and will get damaged in transit to our factory. Parts must come in one of 4 ways

Tape and Reel - cut tape is perfectly acceptable

Tube - the tubes should be sized appropriately for the part and all of the parts in the tube should be facing the same direction. Please do not put parts in the tube 180 degrees (opposite) from other parts

Trays - the tray should be designed specifically for the component. There should be a mating tray of the same type keeping the components stationary in the tray. We have seen some trays come in with a piece of cardboard taped to the top of the tray in an attempt to keep the component in the tray. This will not work. Every time we've seen this done, we've seen many if not all of the components get damaged.

Other package - if the components you have are expensive and you only have them loose with no means of repackaging them, then we'd recommend buying some type of purpose built ESD container that will make sure the components don't get damaged in transit. Something like this would probably work well. But please let us know ahead of time when you are sending components like this. We need to be prepared because our machines cannot pick from anything that is not cut tape, tubes, or trays. It will require we come up with a custom tray solution to pick these components from. We don't mind doing this for especially expensive components.

Useful containers for very expensive loose components.

ESD Sensitive Components

When sending ESD sensitive components, please make sure to use ESD safe packing materials. You’ll want to make sure you’re using an ESD shielded bag and not just ESD resistive or ESD dissipative materials. An ESD shielded bag is really necessary when shipping sensitive components as it creates an ESD barrier and prevent any ESD damage from occurring during transit. Things like “anti-static bubble bags” and “anti-static poly bags” are useful for when handling material around a shop floor, but during transit, shielded bags really are necessary.

Packing List

A packing list must be included in your package. This list can be as simple as a hand written sticky note if it's just a couple of parts. But if it's a larger number of unique parts, then please type up a packing list that includes at least the Part Number and Quantity provided. But the more information provided, the better. Descriptions can be nice because then we can verify that the part labeled matches the description. We've seen plenty of consigned kits where our customer labeled the part one thing (say a 10k resistor) but it was something else (like a 1k resistor). Having the description on the label helped us identify the wrong part before it got soldered to the board.

Here is an example of a packing list a customer sent us that just made our day.

Ideal packing list

Identifying The Package

When you put all of your material into a box to ship to us, please put your company name (or your personal name if you are not a company) along with your Quote Number on the Attention line of the address.

Worthington Assembly Inc.

Attn: Customer Name - Quote Number

14 Industrial Drive East

South Deerfield, MA 01373

United States

If you placed an order through CircuitHub then your address should read like this. You can find this information in the Consignments tab of your Order Page.

re: EChrisDenney/00027f19

Worthington Assembly Inc.

14 Industrial Drive East

South Deerfield, MA 01373

United States

Notify Us

When you finally do consign your kit to us, email your contact here at WAi with the tracking number so that we may pass this along to our receiving department so that they can be on the look out and ensure that your project's kit is received and kitted to the floor in a timely manner. If you placed your order on CircuitHub, create a New Issue and notify us that way.

Return or Stock Material

Sometimes customers like us to stock their consigned material for them so that it can be used in a future project. We have an excellent MRP system where we keep track of all of our material, both internal stock and customer stock. So you can be confident that if you send us material, we will not lose it. But if you'd like to have any of it back, that's fine too. Just communicate that to us ahead of time so that we can clearly identify what material is to be sent back when we label all of your parts during our receiving process.

If you have any questions, please feel free to email us at info@worthingtonassembly.com or give us a call at (413) 397-8260.